Our Sustainnovation

Clean Energy: Clean Energy for a Better World

Previously, many industries relied on coal, a major source of PM2.5 and greenhouse gases but we decided to switch to clean energy.

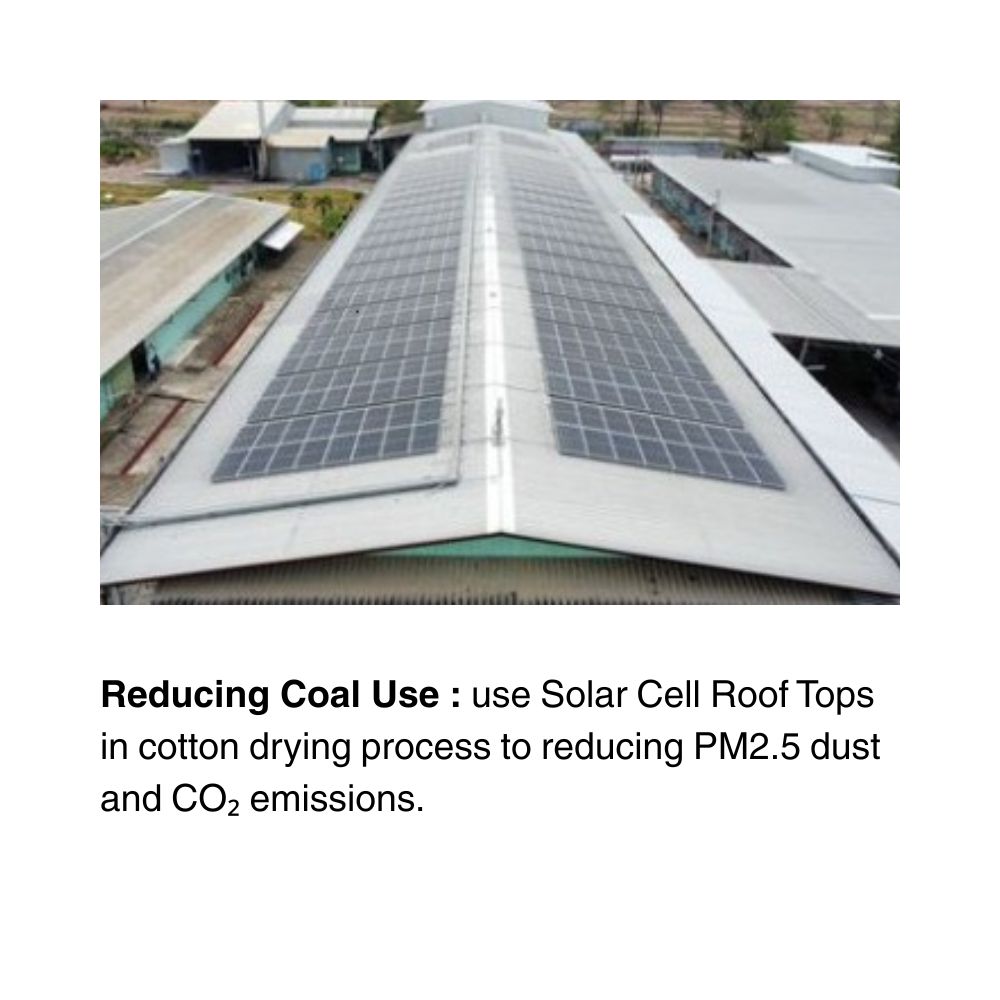

- Reducing Coal Use: We switched to LPG in the cotton drying process to reduce PM2.5 dust and CO₂ emissions.

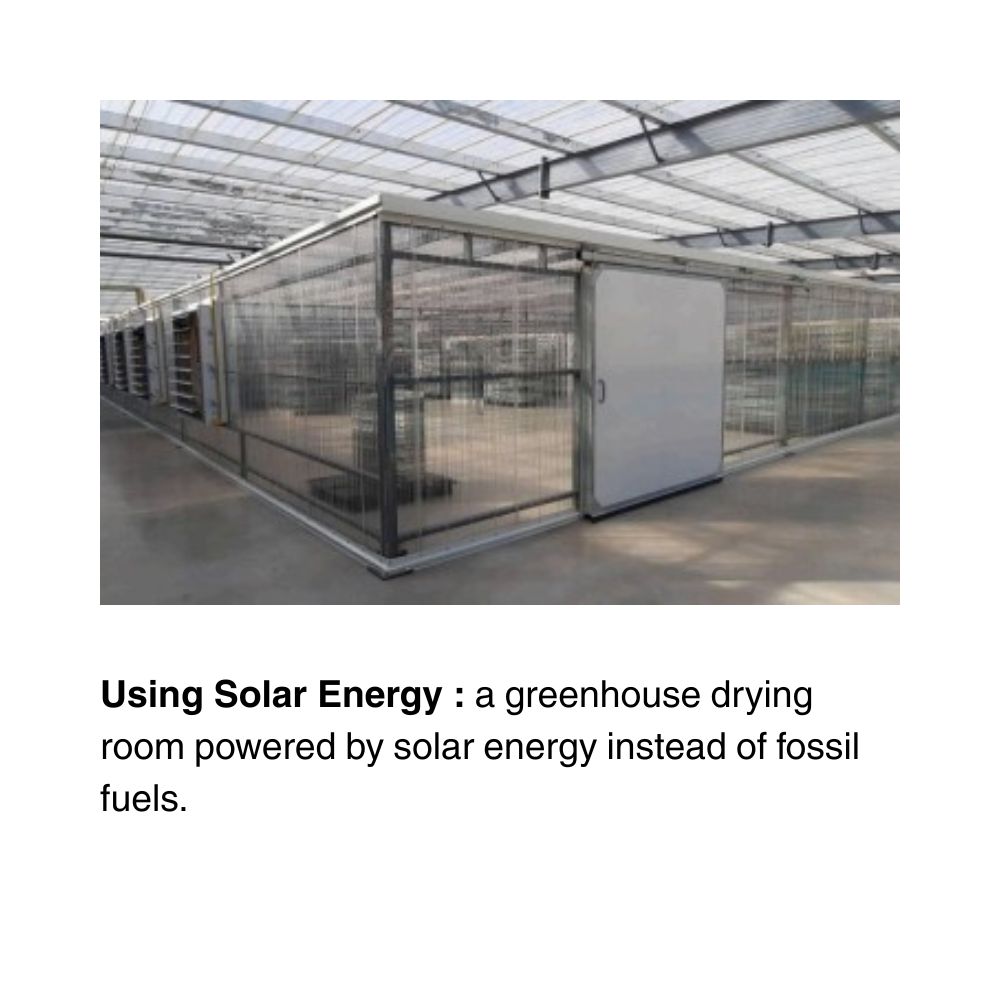

- Using Solar Energy: We experimented with a greenhouse drying room powered by solar energy instead of fossil fuels.

- Switching to Electric Drying: We installed Heat Blowers in P1 areas to eliminate coal use 100%.

- Exploring Renewable Energy Technologies: Such as Once Through Boilers (LPG) and Solar Evacuated Tubes to produce hot water in the bleaching process.

"The energy we release today will determine the world’s future tomorrow."

Cotton from Nature... Returning to Nature

As plastic and industrial waste become major global issues, we choose to be part of the solution rather than the problem.

- We develop cotton swab sticks from paper and biodegradable plastics to reduce environmental waste.

- We reduce plastic in products by using additives that make the plastic sticks thinner while maintaining their original quality.

- We improve our packaging to be more environmental friendly, reducing unnecessary plastic use.

"We are committed to creating good products without harming this world."

Our Future: 100% Environmentally-Friendly Factories

Sustainability doesn’t come from a single change, but from every small decision we make every day.

- Every day, we reduce CO₂ emissions.

- Every day, we choose environmentally friendly materials.

- Every day, we develop production processes that use clean energy.

All of this… is our step toward a sustainable future.

And we want you to be part of this change, not just as a customer, but as a partner in building a better future together.

“Good cotton must also be good for the world.”

Circular Economy: Maximizing Resource Efficiency

In the past, materials left over from the manufacturing process, such as cotton scraps, plastic waste, or by-products from the spinning industry, were often incinerated or landfilled, releasing CO₂ and greenhouse gases.

But we see value in everything that is left behind and have redesigned it into a Circular Economy system.

- Recycling Raw Materials: We use comber noil waste, a by-product from the spinning process, as a key raw material in producing dried cotton pads.

- Reusing Cotton and Plastic Scraps: We recycle clean materials generated in the production process to reduce waste.

- Reducing Chemical Use: We have replaced lye with natural enzymes that are safe and environmentally friendly.

- Developing Waste-Reducing Products: We have designed cotton swab sticks from paper and biodegradable plastic to reduce waste.

"Every scrap of material has value if we use it wisely."